rockwell hardness test knife|knife steel hardness scale chart : white label The Rockwell hardness rating of a knife blade is a key factor that determines its performance and longevity. A knife with a high Rockwell hardness rating, such as a rating of 59-60 HRC, is generally known for its exceptional . WEB16 de dez. de 2023 · 布偶貓 (Ragdoll) ,貓如其名般像個大型娃娃,外表夢幻又帶著可愛,擁有完美的身材比例,又是眾所皆知的超友善個性。. 抱著布偶貓看著他時,整個畫面充滿粉紅泡泡,就連硬漢也都會被他融化。. 到底布偶貓有什麼迷人魔力?. 在照顧上有沒有什麼 .

{plog:ftitle_list}

WEBElisa Sanches. upvotes . Anao transando redgifs upvote r/topsbr. r/topsbr. Members Online. NSFW. Sweetie Fox redgifs upvote r/topsbr. r/topsbr. Members Online. NSFW. Aria Sky redgifs upvote .

The Rockwell hardness rating of a knife blade is a key factor that determines its performance and longevity. A knife with a high Rockwell hardness rating, such as a rating of 59-60 HRC, is generally known for its exceptional . What is Rockwell Hardness Test? The Rockwell hardness test measures the resistance of a material to indentation. The indentation is made with a standardized ball indenter that has a flat circular shape and a radius of .

HRC Rockwell Test - DIY Hardness TestUsually, harder steel increases the likelihood that blade will remain sharp for a longer period of time. Steel hardness . This number helps consumers understand the knife's potential for edge retention, as well as its ability to withstand impact and wear. Understanding the Rockwell Hardness Values: Soft Blades (Low Rockwell Hardness): .It’s a logical assumption, but there are tradeoffs. The Rockwell hardness test allows knifemakers to find a balance that promotes blade sharpness and helps the owner keep it that way. Generally, a knife with a Rockwell Hardness .

When looking at knives you will often see a number in the specs with “RC” after it. This number represents the Rockwell Rating. The Rockwell rating is a scale that is used to measure the hardness of a material. An example is stainless steel AUS-8, which usually 57-59 Rc. The Rockwell hardness test is the industry standard for knives. In the knife industry, the Rockwell hardness test is typically used to measure the hardness of the blade at the spine and edge. The Rockwell scale used for knives is typically the C scale, which measures the hardness of hardened steel. To perform the Rockwell hardness test, a diamond or tungsten carbide ball is pressed into the blade with a .

The hardness of most Japanese knives is between 60 and 62 HRC, they keep an edge for a long time and are easy to resharpen due to steel structure. They are prone to breakage, however, and can get damaged if used incorrectly. Modern steels of powder metallurgy rank highest on the Rockwell scale and boast hardness around 64 and 68 HRC.

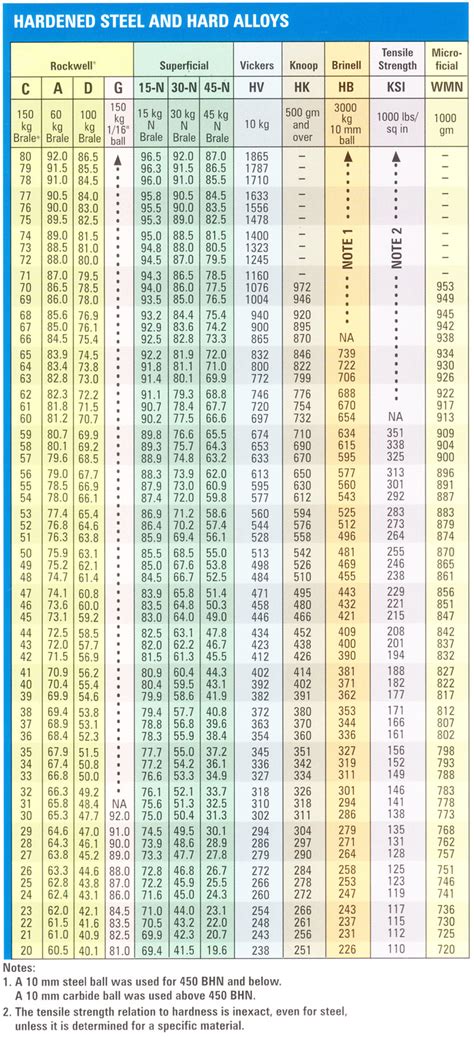

In all, the Rockwell hardness of a knife will always be different between high-end knives and low-end knives, for example, an M390 steel knife is a 62HCR compared to 420Hc steel knife which has a 58HCR, it doesn’t necessarily mean that the M390 is better than the 420HC, yes the M390 Is a premium steel with high quality, but it depends on your usage too, for example, both .Test your knife hardness on the Rockwell C scale with this testing file set. Files from 40 RC to 65 RC are included in a custom-fitted case, along with complete instructions and a conversion chart for Rockwell to Vickers. These high-quality hardness testing files feature specially curved tips for testing internal slots and grooves as well as . What is Rockwell Hardness? (HRC) The Rockwell hardness scale is more than 100 years old and is used for countless applications including engineering, design, and the development of consumer products such as kitchen knives. It’s a scale that measures the hardness and relative strength of various materials, including metal.

Wondering what the Rockwell scale even is? Read on for all you need to know. GRAB GORDON'S GOLDEN TICKET TO LONDON | LEARN MORE. . 16pc Steak Knife and Bistecca Plate Set + 8" Chef's Knife + 3.5" Paring Knife Bundle 9.99 4 22% Savings (157) Aprons Aprons. Eco Modern Apron Benny's Eco .

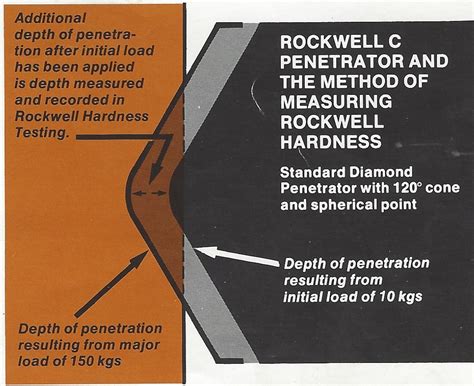

The Rockwell test involves pressing a tiny, precisely shaped, sized indenter into the material's surface. The penetration depth is measured, giving us a hardness number. This number is always followed by a letter that signifies the scale used and the indenter type. For example, you might see . Rockwell Hardness in Knife Manufacturing. CATRA Testing of M390 Knives. . CATRA measured both Vickers and Rockwell hardness on the knives, apparently because they felt that Vickers would be more accurate. They pointed out that the Rc values were about 1 point lower than the values obtained from converting Vickers to Rc. However, conversions between different hardness tests is not an .How the Rockwell Hardness Scale Works Testing process and methodology. The Rockwell hardness test employs a precise and standardized methodology to measure the hardness of metallic materials, including knife blades. The process involves using a diamond-tipped cone indenter that is pressed into the steel surface at two different pressure levels.The hardness test gives you an idea of the flex strength and confirms that the knife’s edge will hold. Although many testers have been used by knife makers, testing with a Rockwell hardness tester provides the most reliable results.

Rockwell hardness scale is the most common unit to identify knife steel hardness. When a knife’s hardness is between HRC 45 and the low-50s, we see it as being on the softer side. Any steel that’s higher than the mid .

How to use Rockwell Hardness Files for knife making. Testing files can be used as an affordable way to test the hardness of knife blades after heat treating.. Most knives are graded using the industry standard for hardness, known as the Rockwell Hardness Scale. The lower a blade’s Rockwell rating, the softer it is, and the more easily it will get dull. In the packages of most kitchen knives, the Rockwell hardness rating for steel is stated by HRC (Hardness Rockwell Scale) or RC, followed by a number stating the hardness and the last letter expressing the type of testing. . The Rockwell hardness test is done by measuring the permanent depth created on a material caused by the force of the .

The Rockwell Hardness Test was created by Stanley P. Rockwell in 1914 as a new way to measure the steel ball bearings manufactured at his company. This test was, eventually, found to measure the strength of any type of metal, as well as non-metallic materials—including knives.

Rockwell Hardness Test We use the Rockwell C (HRC) scale to describe knife hardness, concentrating on the range of 53 to 63. 53 is considered soft – in relative terms – whereas 63 would be considered very hard.

The Rockwell hardness test applies a specific amount of force for a particular time. The results are calculated using a mathematical formula and are expressed as a number on the standard Rockwell scale. For knives, the test is performed on the C scale, with values ranging from 40 to 65. The Rockwell procedure for knife-making involves two . Shun Knives Rockwell Hardness (HRC) HRC stands for Rockwell Hardness—a standardized method of measuring how hard any given steel is. The higher the number, the harder the steel. Your average German knife, made with German steel, comes in around HRC 57. Shun (with one exception that I know of) heat treats all its knives to HRC 60-61. Rockwell hardness is a simple test for checking the relative strength of materials. It works by indenting steel with a fixed load and measuring the distance that the indenter travels into the steel. It is commonly used by knifemakers, heat treaters, and knife companies.

Rockwell Hardness and Bushcraft Knives. January 25, 2015. By Bushcraft. . The Rockwell test determines the hardness by measuring the depth of penetration of an indenter under a large load compared to the penetration made by a preload. There are different scales, denoted by a single letter, that use different loads or indenters. .The Rockwell Hardness Test is generally a non-destructive test performed on samples when it’s necessary to determine how hard a material is. . often use the Rockwell hardness HRC scale. For example, the hardness of solid kitchen knives starts around 56 HRC. These blades are tough and ductile, but they quickly lose their edge and are harder . ASTM E10: This standard covers Brinell hardness testing in metallic samples. ASTM E18: This standard includes the various ways that Rockwell hardness can be measured by standard methods, specifically for metallic materials. ASTM E384: This standard is for hardness testing on a micro-scale, and therefore includes the Vickers and Knoop hardness .

The Rockwell hardness test is also crucial when selecting the appropriate steel for different types of knives. For example, a fillet knife, which requires flexibility, might have a lower Rockwell hardness compared to a cleaver that needs to withstand chopping through bone. . The Impact of Rockwell Hardness on Knife Maintenance. The .

rockwell hardness scale pdf

concrete hardness tester pce ht 225a

concrete hardness tester virginia beach

WEBInside Riley 1: Com a ausência de sua mãe, Riley um estudante muito sexy. Pediu pro seu pai passar uma pomada na sua buceta. Porém toda essa situação acaba deixando o pai .

rockwell hardness test knife|knife steel hardness scale chart